What are Sheet Metal Quality and Properties?

Sheet metal qualities and properties are wondered by people who will use sheet metal, which has become more suitable for building projects. With the technological developments in the building materials sector in recent years, sheet metal, which has many different types, has become a more economical and robust material preference for the buildings being built.

Due to the presence of many different manufacturers, sheet metal qualities and properties vary considerably. Therefore, it is necessary to learn what to pay attention to when choosing this material that contributes to the durability of buildings and increases the comfort of living spaces. In our content, we will answer the question of what sheet metal qualities and properties are, and we will also list what sheet metal types are.

What is Sheet Metal?

Sheet metal is the name given to sheets that have been formed into thin, flat pieces by an industrial process. This material is offered to customers in flat pieces or coil strips. Coils are formed by continuously passing the sheet metal through a cutter. Sheet metal is one of the basic forms used in metal processing and can be cut and bent into various shapes. Sheet metal is also used in the production of countless products encountered in daily life.

What are Sheet Metal Qualities and Properties?

With the development of building sector technology, the materials used in construction projects have also become more diverse. Sheet metal, which is one of the most preferred materials, is among the products that have diversified with technological developments. The quality and properties of the sheet metal produced with different raw materials such as steel and aluminum vary according to the area of use.

Exactly for this reason, it is necessary to prefer sheets produced in accordance with the areas to be applied in building projects. Although sheet metal qualities and properties vary according to the raw material it is produced from, they all help to increase the durability of buildings.

Almost all common building metals are used by forming them into sheet metal. The most preferred metal types for sheet metal production are carbon steel, stainless steel, copper, and aluminum. The most important thing to know at this point is that steel sheets have the same mechanical properties as metal. Therefore, steel sheets have high tensile strength and durability suitable for use in construction and machinery.

What are the Types of Steel Sheets?

There are 7 types of sheet metal materials, each with different qualities and properties. These different materials, all of which have metal as their main raw material, have various areas of use.

1. Alloy Steel Sheet

An alloy steel sheet is a type of steel sheet that, in addition to carbon, is used to enhance various properties of the material. Alloy steel sheets can contain a wide variety of elements, each of which can improve various properties of the material, such as mechanical thermal and corrosion resistance. Alloy steel sheets, whose elements are usually manganese, nickel, chromium, molybdenum, vanadium, silicon, and boron, tend to improve the mechanical properties of the structure with these additions. For example, while increasing the hardness and strength of the structure in which it is used, it also increases corrosion resistance and stability at high or low temperatures.

2. Stainless Steel Sheet

Stainless steel sheets, which are frequently preferred for decorative purposes along with their appearance, have a shiny appearance as their most important feature. As the name suggests, another important reason why these sheets, which have stainless properties, are frequently preferred is that they are self-repairable. Stainless steel sheets are frequently used in living spaces thanks to their resistance to impacts and inexpensive repair.

Stainless steel sheets, which have high resistance to high temperatures and impacts, can be used in many different areas. Different areas where it is mainly used;

- Kitchens

- Fuel Tankers

- Production Facilities

- Medical Industry

- White Appliances

3. Carbon Steel Sheet

A carbon steel sheet is made from an alloy of iron and carbon. Carbon steel sheets are one of the most widely used forms of steel in the world. Due to its alloy structure, it can contain various elements such as chromium, nickel, and vanadium. It is generally preferred in building interiors and in areas where increased durability and insulation are desired.

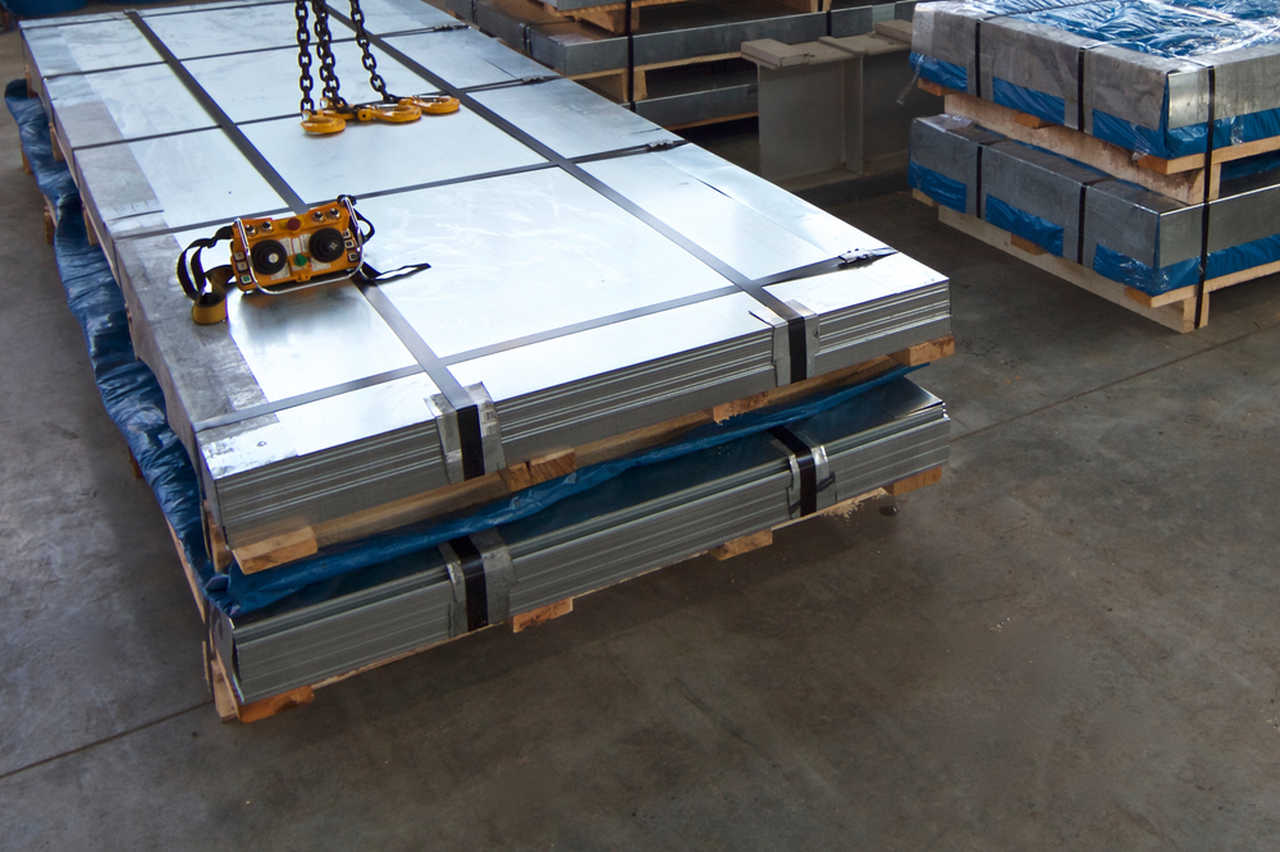

4. Galvanized Steel Sheet

Galvanized steel sheet, which is one of the first materials that come to mind when it comes to sheet qualities and properties, is a type of steel sheet used to help prevent corrosion in structures. These sheets are used not only in building projects but also in a variety of different applications, including furniture and car construction. This process is done to help prevent corrosion caused by the steel being exposed to other metals or oxygen and water in the presence of an electrolyte.

The process of producing galvanized steel sheets usually begins by dipping the sheet in zinc, which has high temperatures. After the steel is galvanized, the zinc coating reacts with oxygen to form zinc oxide. Over time, zinc hydroxide reacts with carbon dioxide to form zinc carbonate, a gray layer that slows the reaction rate of the zinc and helps protect the steel.

5. Titanium Sheet

Titanium has several advantages that make it suitable for a variety of industrial applications. Primarily due to its high strength and weight ratio suitable for structures, it offers high recyclability, durability, and biocompatibility, although it is also used for corrosion resistance. Typical uses include aerospace parts, medical equipment, and structural elements.

6. Galvalume Sheet

When steel is galvanized with an alloy of aluminum, zinc, and traces of silicon, it is called galvalume. The resulting product becomes more durable and more resistant to corrosion than galvanized steel. Due to the material's superior corrosion resistance, galvalume sheets are used for outdoor applications such as roofs that are regularly exposed to the weather.

7. Trapezoidal Sheet

Trapezoidal sheet, also known as roofing sheet, is an exterior cladding material produced using galvanized thin sheet metal and painted as a result of the baking process, is among the most preferred sheet types in recent years. The high durability and aesthetic appearance that trapezoidal sheet metal provides to structures ensures that the structures to which it is applied have an industrial design. Trapezoidal sheet metal, which is mostly preferred for roof and facade cladding and offers economical solutions, is frequently preferred in industrial buildings, residences, and prefabricated buildings.

Ayba Metal, which has more than 20 years of experience in the metal sector, stands out with the durability of trapezoidal sheets drawn on special rollform lines in its state-of-the-art production facilities.

As Ayba Metal, the prefabricated building and drywall profile brand, we have given the subject of sheet metal qualities and properties in our content by listing popular sheet types. Ayba Metal, one of the most preferred companies among galvanized sheet metal manufacturers, continues to produce different products that will meet the needs of its customers under the leadership of its expert management staff.

You can also examine the building materials among Ayba Metal's wide product range, and you can have all the products you need for your construction and decoration projects with the most affordable price options. You can also contact Ayba Metal for all your questions.

Also, don't forget to visit our blog with informative content about the building and construction world!